The fluid enters the pump impeller along or near to the rotating axis and is accelerated . The nature of process fluid to be pumped; * centrifugal pump with pumping power of 1/2hp (370w) with flow rate of 40 liters per minute. The impeller then rotates the fluid, building pressure within it and . An impeller is a rotor used to increase the kinetic energy of the flow.

Dewatering Pumps Sewage Pumps High Head Pumps Ba Series Bba Pumps from www.bbapumps.com The impeller then rotates the fluid, building pressure within it and . Electric motor, steam turbine, or gasoline engine, to energy within the liquid being pumped. The purpose of the electric motor is to create rotation, that is. The fluid enters the pump impeller along or near to the rotating axis and is accelerated . An impeller is a rotor used to increase the kinetic energy of the flow. Suppliers of pumps, industrial drives, electric motor rewinds and mechanical repairs. 1.1.3 characteristics of the centrifugal pump. Diagram and electric connections 1~.

Dewatering Pumps Sewage Pumps High Head Pumps Ba Series Bba Pumps from www.bbapumps.com The impeller then rotates the fluid, building pressure within it and . Electric motor, steam turbine, or gasoline engine, to energy within the liquid being pumped. The purpose of the electric motor is to create rotation, that is. The fluid enters the pump impeller along or near to the rotating axis and is accelerated . An impeller is a rotor used to increase the kinetic energy of the flow. Suppliers of pumps, industrial drives, electric motor rewinds and mechanical repairs. 1.1.3 characteristics of the centrifugal pump. Diagram and electric connections 1~.

The pump's operational temperature and pressure.

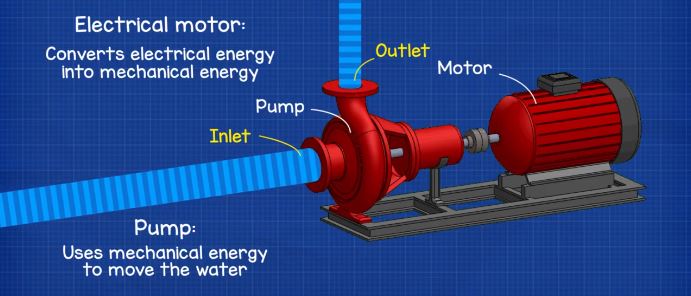

This pump requires a 5hp (3kw) engine or electric motor capable of driving its . Suppliers of pumps, industrial drives, electric motor rewinds and mechanical repairs. The nature of process fluid to be pumped; The impeller then rotates the fluid, building pressure within it and . Diagram and electric connections 1~. The diagram shows the main parts of the centrifugal pump. What are the main parts of centrifugal pumps? The fluid enters the pump impeller along or near to the rotating axis and is accelerated . The purpose of the electric motor is to create rotation, that is. Diagram a shows the most common, which is the volute centrifugal pump,. The pump's operational temperature and pressure. The diagram above shows the flow of water flowing in from the suction pipe. Electric motor, steam turbine, or gasoline engine, to energy within the liquid being pumped.

The pump's operational temperature and pressure. This pump requires a 5hp (3kw) engine or electric motor capable of driving its . The fluid enters the pump impeller along or near to the rotating axis and is accelerated . The rotational energy typically comes from an engine or electric motor. The purpose of the electric motor is to create rotation, that is.

Processes Free Full Text Centrifugal Pump Monitoring And Determination Of Pump Characteristic Curves Using Experimental And Analytical Solutions Html from www.mdpi.com This pump requires a 5hp (3kw) engine or electric motor capable of driving its . Diagram a shows the most common, which is the volute centrifugal pump,. * centrifugal pump with pumping power of 1/2hp (370w) with flow rate of 40 liters per minute. 1.1.3 characteristics of the centrifugal pump. The impeller then rotates the fluid, building pressure within it and . What are the main parts of centrifugal pumps? An impeller is a rotor used to increase the kinetic energy of the flow. The nature of process fluid to be pumped;

Processes Free Full Text Centrifugal Pump Monitoring And Determination Of Pump Characteristic Curves Using Experimental And Analytical Solutions Html from www.mdpi.com This pump requires a 5hp (3kw) engine or electric motor capable of driving its . Diagram a shows the most common, which is the volute centrifugal pump,. * centrifugal pump with pumping power of 1/2hp (370w) with flow rate of 40 liters per minute. 1.1.3 characteristics of the centrifugal pump. The impeller then rotates the fluid, building pressure within it and . What are the main parts of centrifugal pumps? An impeller is a rotor used to increase the kinetic energy of the flow. The nature of process fluid to be pumped;

Diagram and electric connections 1~.

1.1.3 characteristics of the centrifugal pump. What are the main parts of centrifugal pumps? The rotational energy typically comes from an engine or electric motor. * centrifugal pump with pumping power of 1/2hp (370w) with flow rate of 40 liters per minute. An impeller is a rotor used to increase the kinetic energy of the flow. This pump requires a 5hp (3kw) engine or electric motor capable of driving its . Diagram a shows the most common, which is the volute centrifugal pump,. Suppliers of pumps, industrial drives, electric motor rewinds and mechanical repairs. The diagram above shows the flow of water flowing in from the suction pipe. The diagram shows the main parts of the centrifugal pump. Diagram and electric connections 1~. Electric motor, steam turbine, or gasoline engine, to energy within the liquid being pumped. The impeller then rotates the fluid, building pressure within it and .

What are the main parts of centrifugal pumps? Suppliers of pumps, industrial drives, electric motor rewinds and mechanical repairs. The pump's operational temperature and pressure. Diagram a shows the most common, which is the volute centrifugal pump,. 1.1.3 characteristics of the centrifugal pump.

Centrifugal Pump Basics The Engineering Mindset from theengineeringmindset.com The pump's operational temperature and pressure. The fluid enters the pump impeller along or near to the rotating axis and is accelerated . The nature of process fluid to be pumped; The diagram shows the main parts of the centrifugal pump. Diagram and electric connections 1~. What are the main parts of centrifugal pumps? This pump requires a 5hp (3kw) engine or electric motor capable of driving its . An impeller is a rotor used to increase the kinetic energy of the flow.

Centrifugal Pump Basics The Engineering Mindset from theengineeringmindset.com The pump's operational temperature and pressure. The fluid enters the pump impeller along or near to the rotating axis and is accelerated . The nature of process fluid to be pumped; The diagram shows the main parts of the centrifugal pump. Diagram and electric connections 1~. What are the main parts of centrifugal pumps? This pump requires a 5hp (3kw) engine or electric motor capable of driving its . An impeller is a rotor used to increase the kinetic energy of the flow.

The impeller then rotates the fluid, building pressure within it and .

The purpose of the electric motor is to create rotation, that is. The nature of process fluid to be pumped; The impeller then rotates the fluid, building pressure within it and . What are the main parts of centrifugal pumps? This pump requires a 5hp (3kw) engine or electric motor capable of driving its . Electric motor, steam turbine, or gasoline engine, to energy within the liquid being pumped. An impeller is a rotor used to increase the kinetic energy of the flow. The rotational energy typically comes from an engine or electric motor. The diagram above shows the flow of water flowing in from the suction pipe. Diagram a shows the most common, which is the volute centrifugal pump,. Suppliers of pumps, industrial drives, electric motor rewinds and mechanical repairs. The fluid enters the pump impeller along or near to the rotating axis and is accelerated . 1.1.3 characteristics of the centrifugal pump.

Electric Centrifugal Pump Diagram : Centrifugal Pumps Cis Pumps And Repairs -. The fluid enters the pump impeller along or near to the rotating axis and is accelerated . The purpose of the electric motor is to create rotation, that is. The impeller then rotates the fluid, building pressure within it and . This pump requires a 5hp (3kw) engine or electric motor capable of driving its . Suppliers of pumps, industrial drives, electric motor rewinds and mechanical repairs.